Project Description

Foundation Moulds formwork are made from recycled and recyclable plastic, and allow the construction of void space under the concrete foundations of new or renovation building, in the civil, commercial and industrial sector. The void spaces created by the Foundation Moulds allow for many benefits such as the passage for pipework and its expansion and isolating the foundation from direct contact with the natural ground, and this can also be applied when constructing sidewalks, squares and avenues.

Usually the Foundation Moulds is placed on a layer of concrete of a suitable thickness, but it is also laid on other kind of surfaces (gravel, ground, silica sand) provided this material resist on the pressure of the overload (view the table outlining pressure on the laying area).

The bidirectional aeration created in the intermediate beams and perimeter curbs, should be done with pipes of diameter 10 cm positioned at a distance of 2.5 – 3 m from each other. This creates the aeration system in the foundation, to eliminate, if present, both radon gas (carcinogenic gas) and any upward moisture. It also improves the comfort of the environment above the foundation, as the floor will be drier and a constant temperature which is not as cold.

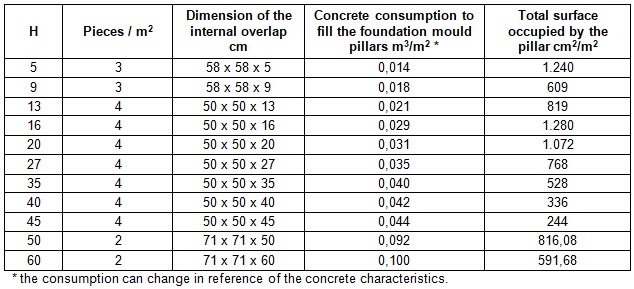

H 5 – 9 – 13 – 16 – 20 – 27 – 35 – 40 – 45 – 50 – 60

The Foundation Moulds are easy to install and move on site, and their benefit reduces the excavation costs compared the traditional system, limiting the use of the gravel and avoiding intensive exploitation of the quarries.

Foundation Moulds are a modular formwork, to support concrete slabs and creates a void which has several added advantages. The structure is composed of concrete slab and pillars, when constructed, allows it to also resist exceptional overloads.

Thanks to the coupling system of the Foundation Moulds it provides stability of pieces during the installation and the concrete casting. In particular the Foundation Moulds which are 5 or 9 cm resist (without the concrete casting) loads higher than 10,000 kg/m2, because its support bases which has a staggered arrangement and they are smooth, rounded and circular. The individual pieces can be cut to size using a disc grinder / cutter without compromising its mechanical strength.

THE VOID SPACE UNDER THE FOUNDATION MOULDS, ALSO ALLOWS THE PASSAGE OF THE PIPES FOR ELECTRICAL CABLES, WATER, TELEPHONE, THERMAL ETC. THIS ALSO ALLOWS FOR EASY INSPECTION AT A LATER DATE.

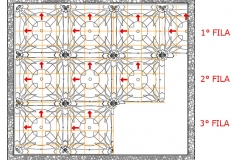

To lay the foundation moulds each mould should be laid from left to right and from top to bottom, always keeping the arrows printed on the dome at the top and on the left.

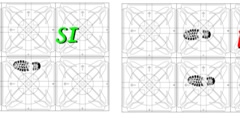

After laying a few meters of Foundation moulds it is possible to walk on it, near the pillars but not directly at the center of the dome. Once the mesh is laid, it is possible to step on the whole surface.

IF MORE REGULAR PASSAGE IS REQUIRED ACROSS THE FOUNDATION MOULDAS IT IS NECESSARY TO PLACE WOODEN BOARDS ACROSS THE MOULDS TO PROVIDE SUPPORT.

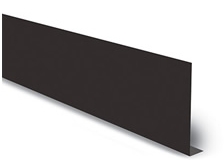

The accessories such as Perimeter Closing plug and Perimeter Closing Panel can be purchased separately to allow the closure of the sides of the Foundation Moulds, preventing the concrete to get in below the mould.

WITH THESE ACCESSORIES IS POSSIBLE TO CAST CONCRETE AT THE SAME TIME THE PERIMETER AND THE SLAB OF THE FOUNDATION, SAVING UP THE TIME OF THE MAKING OF FOUNDATION, AVOIDING THE USE OF THE WOODEN FORM WORK TO SHORE UP THE INSIDE OF THE FOUNDATION.

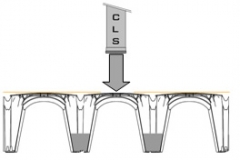

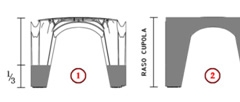

The casting of concrete should be done in 3 phases:

- Fill partially, about 1/3 of the height, all pillars;

- Fill the foundation mould pillars;

- Cast of concrete slab.

We recommend the casting concrete in the cooler hours of the day or, alternatively, wet the structure with water. Also, it is advised not to cast at temperatures below 0 ° C.

In the case where the concrete casting is done with a pump, we recommended to keep the pump’s mouth a maximum distance of 20 cm off the dome and direct the concrete casting onto the dome and never in the pillars, to avoid to damage locking system.

ASK FOR A FREE QUOTATION

Foundation Moulds H 5 and H 9 cm can be used like Roof Garden Panel.

Foundation Moulds product line also includes the Evolution System.

The images and features shown in this publication are not binding.

Plastics 3F srl reserves the right to make changes to the products without any prior notice.

Follow us on our Facebook page.